ROBOTICS

ROBOTICS

Menu

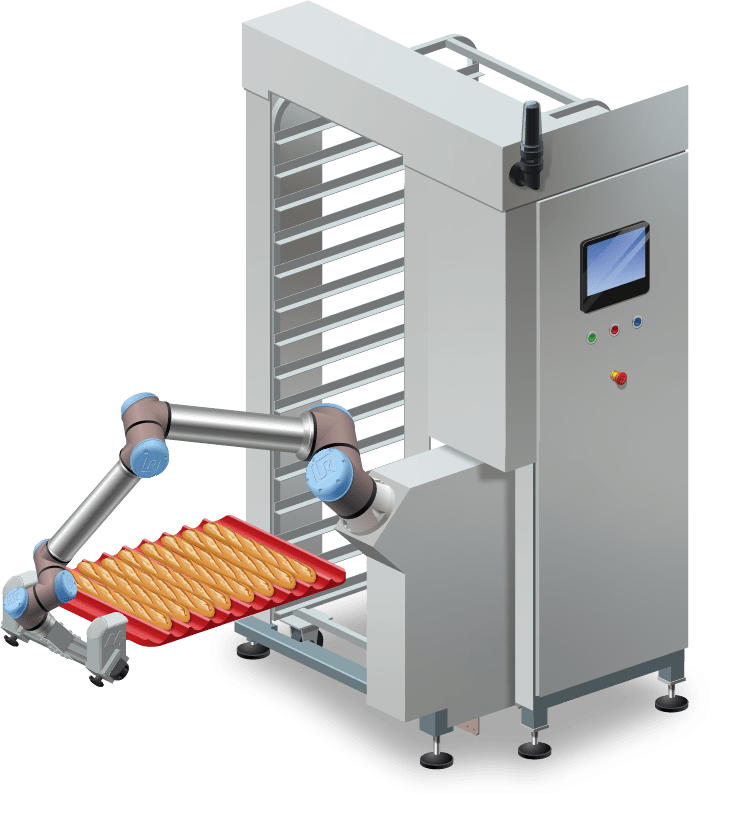

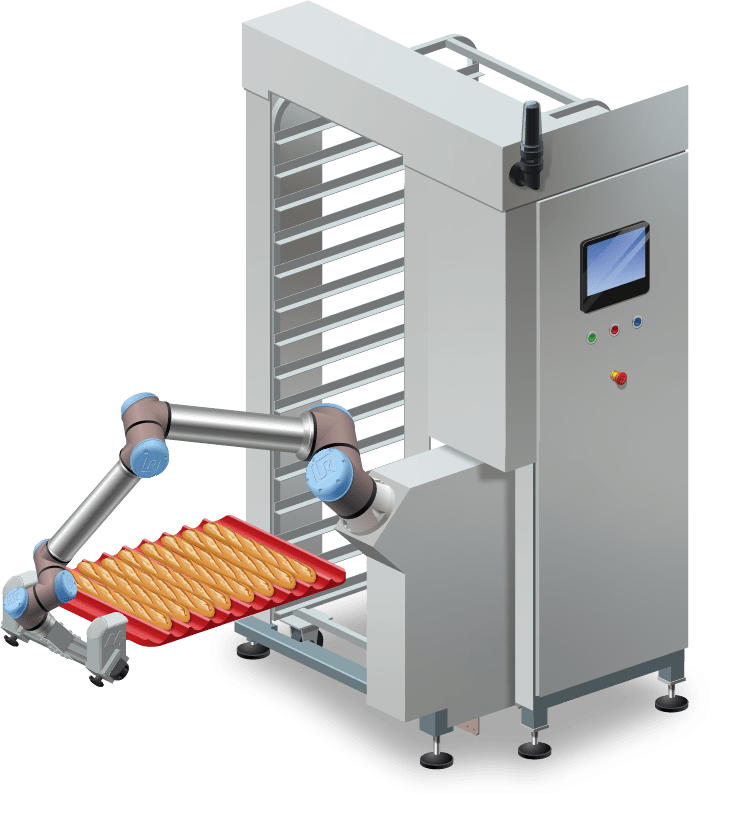

TRAY HANDLER

The compact and flexible solution for

handling trays in industrial processes

TRAY HANDLER

The compact and flexible solution for handling trays in industrial processes

TRAY HANDLER is a universal piece of equipment that serves machines or equipment with various functions such as machine tending, loading or unloading carts, or point-to-point handling without a cart.

TRAY HANDLER is a universal piece of equipment that serves machines or equipment with various functions such as machine tending, loading or unloading carts, or point-to-point handling without a cart.

versatile

It adapts to any machine or line and is available in different configurations, from 0 to 2 carts, to fit production needs and space availability. The robot manipulator can completely move away from the work area, leaving the space available for manual or cleaning operations.

Productive

It ensures repeatability of cycle times throughout the day, from the first cycle to the last, providing a substantial improvement in productivity and availability 24/7. In addition, it allows to significantly increase the autonomy of productive equipment and provide more time to the operator for tasks of greater added value.

Safe and healthy

Interact with operators safely and avoid injuries and illnesses caused by handling loads.

versatile

It adapts to any machine or line and is available in different configurations, from 0 to 2 carts, to fit production needs and space availability. The robot manipulator can completely move away from the work area, leaving the space available for manual or cleaning operations.

Productive

It ensures repeatability of cycle times throughout the day, from the first cycle to the last, providing a substantial improvement in productivity and availability 24/7. In addition, it allows to significantly increase the autonomy of productive equipment and provide more time to the operator for tasks of greater added value.

Safe and healthy

Interact with operators safely and avoid injuries and illnesses caused by handling loads.

No complications

It is very easy to operate, without the need for specific programming or robotics knowledge.

Online

Generate and record valuable productive data accessible locally and from the cloud thanks to the Cloud Monitor. In addition, it can be linked to the MES system and other Industry 4.0 components.

Profitable

Reduces handling costs and losses due to human error. It is a reliable, standardized and reusable technology for a safe investment and a quick return on it.

No complications

It is very easy to operate, without the need for specific programming or robotics knowledge.

Online

Generate and record valuable productive data accessible locally and from the cloud thanks to the Cloud Monitor. In addition, it can be linked to the MES system and other Industry 4.0 components.

Profitable

Reduces handling costs and losses due to human error. It is a reliable, standardized and reusable technology for a safe investment and a quick return on it.

Technological advantages

Based on high-end collaborative robots: Universal Robots

Simple and quick setup

Very simple design with few components

Compact and modular design, easily expandable and reconfigurable

A single source of energy

Easy maintenance

Easy to install and relocate

High energy efficiency: average of 0.6 kW in operation

Technological advantages

Based on high-end collaborative robots: Universal Robots

Simple and quick setup

Very simple design with few components

Compact and modular design, easily expandable and reconfigurable

A single source of energy

Easy maintenance

Easy to install and relocate

High energy efficiency: average of 0.6 kW in operation

* Measurements subject to the dimensions of the cart